Portfolio

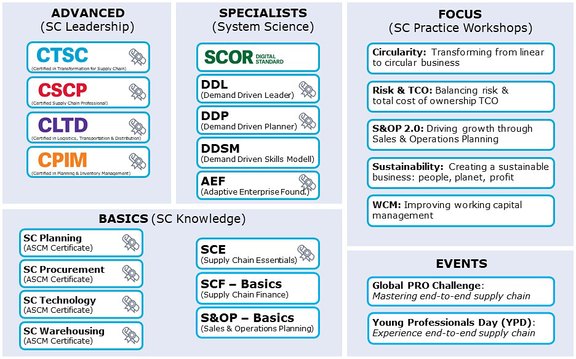

To fulfill all your needs for Supply Chain Education, Training and Certification and to transform your organization towards Supply Chain Excellence, PMI has built an extensive portfolio of Supply Chain and Operations Management Education and Certification programs and Logistics and Supply Chain Management events.

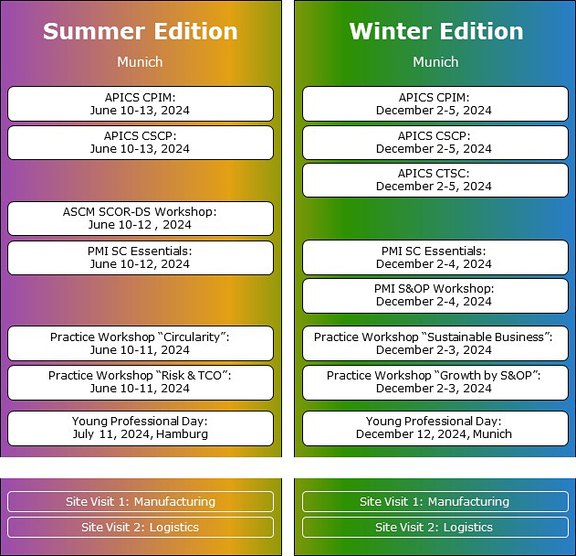

Starting 2024, all public seminars and workshops will be embedded in the Supply Chain Learning Days.

Join us as we bring together industry-leading experts, top-notch trainers, and passionate supply chain professionals for a transformative event. Discover the latest trends, strategies, and best practices in supply chain management that will empower you to excel in your career. Don't miss out on this opportunity to network with fellow practitioners, exchange insights, and explore new possibilities.